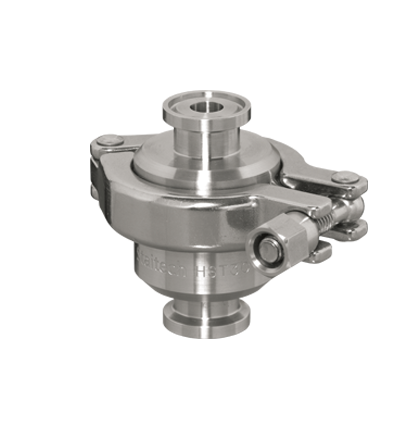

Clean Steam Traps

Staitech HST20, HST30 and HST30TC balanced pressure thermostatic clean steam traps – suitable for a wide range of clean steam condensate drainage, SIP, and system air venting applications in high purity steam systems.

The Staitech HST range of clean steam traps share a number of common design features which include:

- Near-to-steam operating characteristic

- 316L stainless steel construction

- ASME BPE compliant clamp and weld connections

- DIN and ISO size options

- Available in low ferrite/low sulphur materials

- Electropolished finish option

- EN 10204:2004 3.1 Full component traceability

- FDA and USP Class VI compliant body seal