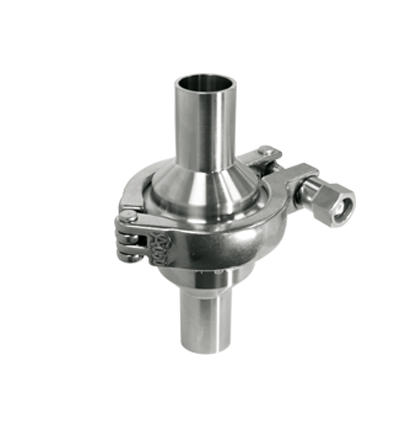

Check Valves

Staitech HCV02, HCV04 and HCV05 check valves – designed specifically for high purity steam, liquid and gas duties in the pharmaceutical industry.

The Staitech HCV range comprises three models, all of which share a number of common design features:

- Steel construction

- 316L stainless ASME BPE compliant clamp and weld connections

- DIN and ISO sizes available

- Low ferrite/low sulphur material options

- Wetted surfaces finished to 0.5 microns Ra

- Electropolished finish option

- EN 10204:2004 3.1 Full component traceability

- FDA and USP Class VI compliant body seal