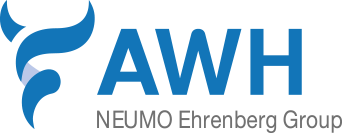

Sanitary Angle-Type Strainers

For coarse cleaning and filtration of liquid flows of low-viscosity flowing media like water, steam, liquid food and drinks with high hygienic requirements.

- Flexible slot widths from 50 µm to 4 mm possible

- DN25 – DN150

- Ra ≤ 0.8 µm – Electro-polished external

Pump Y-Type Strainers

AWH dirt traps protect the product and the process system, pumps and heat exchangers against damage from foreign bodies.

- Slot widths 1 mm, 0.5 mm and 0.25 mm

- DN25 – DN150

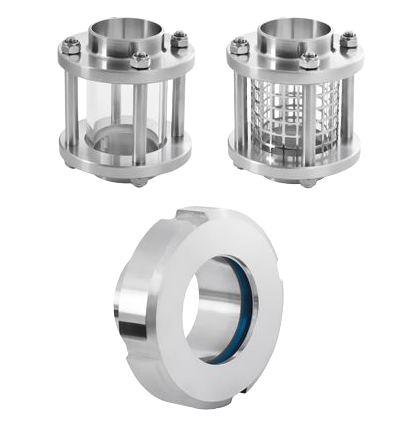

Sight Glasses

- Inline sight glass (Tubular) DN10 – 150

- Pipeline sight glass: (Single/double window) DN25 – DN150

- Tank Level Glass: DN20 x 3M (Larger on request)