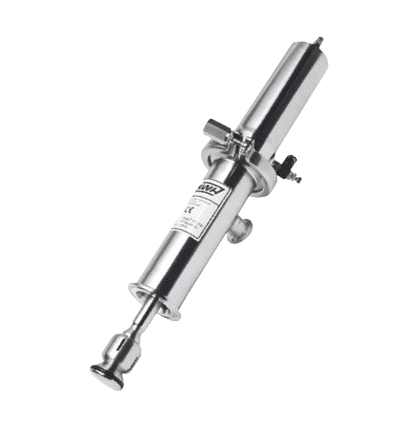

AWH are experts in CIP, designing and manufacturing economically efficient spray heads for cleaning of vessels and tanks.

Range and Standards

- 3-A Sanitary Standards

- ATEX-products

- Engineered solutions for each cleaning task

- Huge quantity of products on stock

- 100 years experience in stainless steel handling

- Made in Germany

Certified Manufacture

- Certified fabrication and quality service acc. to ISO 9001

- ASME-BPE, 3-A or EHEDG compliant

- FDA-compliant products

- Certificates: material 3.1, delta-Ferrite, Ra, ATEX, USP CL VI

Materials

- 316L (1.4404/1.4435)

- 316Ti (1.4571)

- HC22 (2.4602)

- HC4 (2.4610)